A well designed and properly fabricated stainless-steel exhaust can be the absolute highlight of a custom motorcycle, both in looks and performance. Week after week we have service customers walking in the door looking for the latest and greatest exhaust just to squeeze out a few more horses and dazzle everyone at bike night. Its no wonder there are so many after market companies making custom exhausts today. Stainless steel has become increasingly more popular due to the unique look and beautiful welds. But stainless steel exhaust systems must be properly fabricated or the welds will not last long at all. It is absolutely necessary that the back side of a thin stainless steel weld be shielded from the atmosphere during the weld process. Purging the exhaust with argon gas is the preferred method of shielding a stainless steel weld.

The motorcycle after market is a relatively small industry. Independent service shops and individual parts fabricators have the daunting task of competing against much larger corporations with vastly more resources. The only real advantage a very small shop or individual has is a lower financial cost or overhead. This can allow the “little guy” to spend more time on a product, and potentially bring a very high-quality part to market.Unfortunately, this is not always the case. The desire for money and social media fame drives some small shops (and individuals) to compromise integrity attempting to undercut everyone else.I discovered such a company this month when a new customer walked in the doors at Faith Forgotten Choppers.

This gentleman had purchased an aftermarket exhaust that was marketed as a high performance and high quality product. Well his exhaust had fractured and he had purchased a replacement for the same company. He brought the new exhaust my shop for Corey to install. Now, I’m well aware that there are many factors that can cause an exhaust to crack, and it is not always the manufacturers fault. But in this case the cause of the weld fracture was very clear.

I happened to walk into the show room and overhead my manager Craig discussing this fractured exhaust with our new customer. I walked outside to get a good look at the problem. To my surprise the crack was in the very center of the weld. Generally, a crack will occur at the outside edge (grain barrier) of a weld. This centerline crack lead me straight back in to inspect the duplicate exhaust he had brought for replacement.

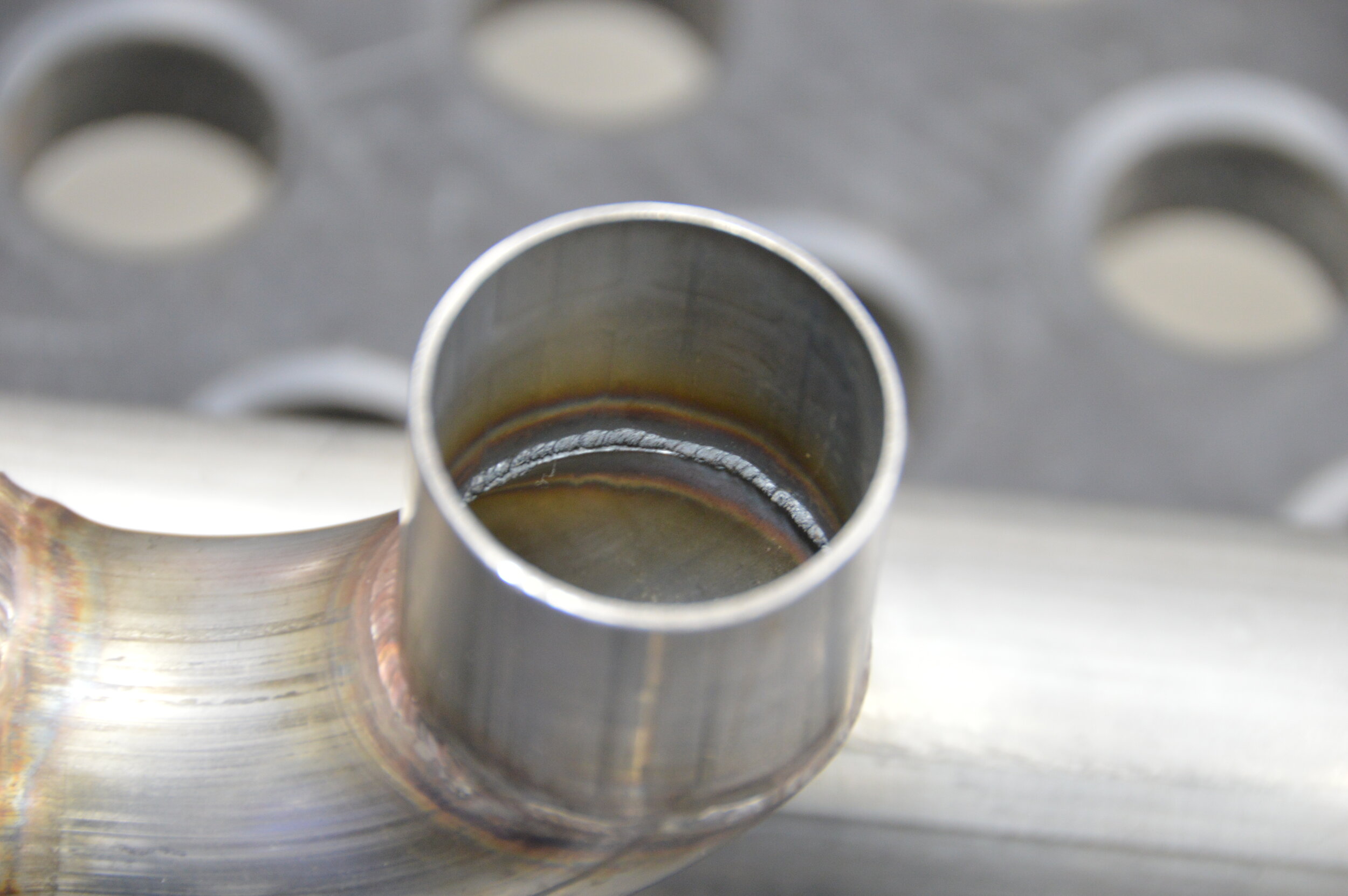

As I expected the inside of the stainless weld was heavily oxidized (sugared) and thus lacked fusion. This exhaust was not purged when it was welded. It is my opinion that this is simply an unacceptable practice for a professional shop. We encouraged our customer to return the exhaust and let us order him a product from a more reputable company as this replacement would most surely break again.

For demonstration purpose, I welded two pieces of stainless exhaust tubing together using an argon purge. You can clearly see the difference between the inside of my weld and the weld from fractured exhaust manufacturer. The inside of this purged weld shows complete fusion and no sign of oxidation. Aside from being much stronger, the purged weld lies flat and will not interrupt the exhaust gas flow, which in turn will result in better performance.

This photo illustrates some of the items I use for purging a stainless steel exhaust system during the weld process.

It is necessary to have either a separate tank of argon or build a custom system that employs two separate flow meters in order to properly set the flow rate of the purge. The system I have build includes an entire argon purification system and replaces all vinyl tubing with stainless steel Swaglock tubing and connectors, ensuring a shielding gas with a contamination factor measured in parts per billion.

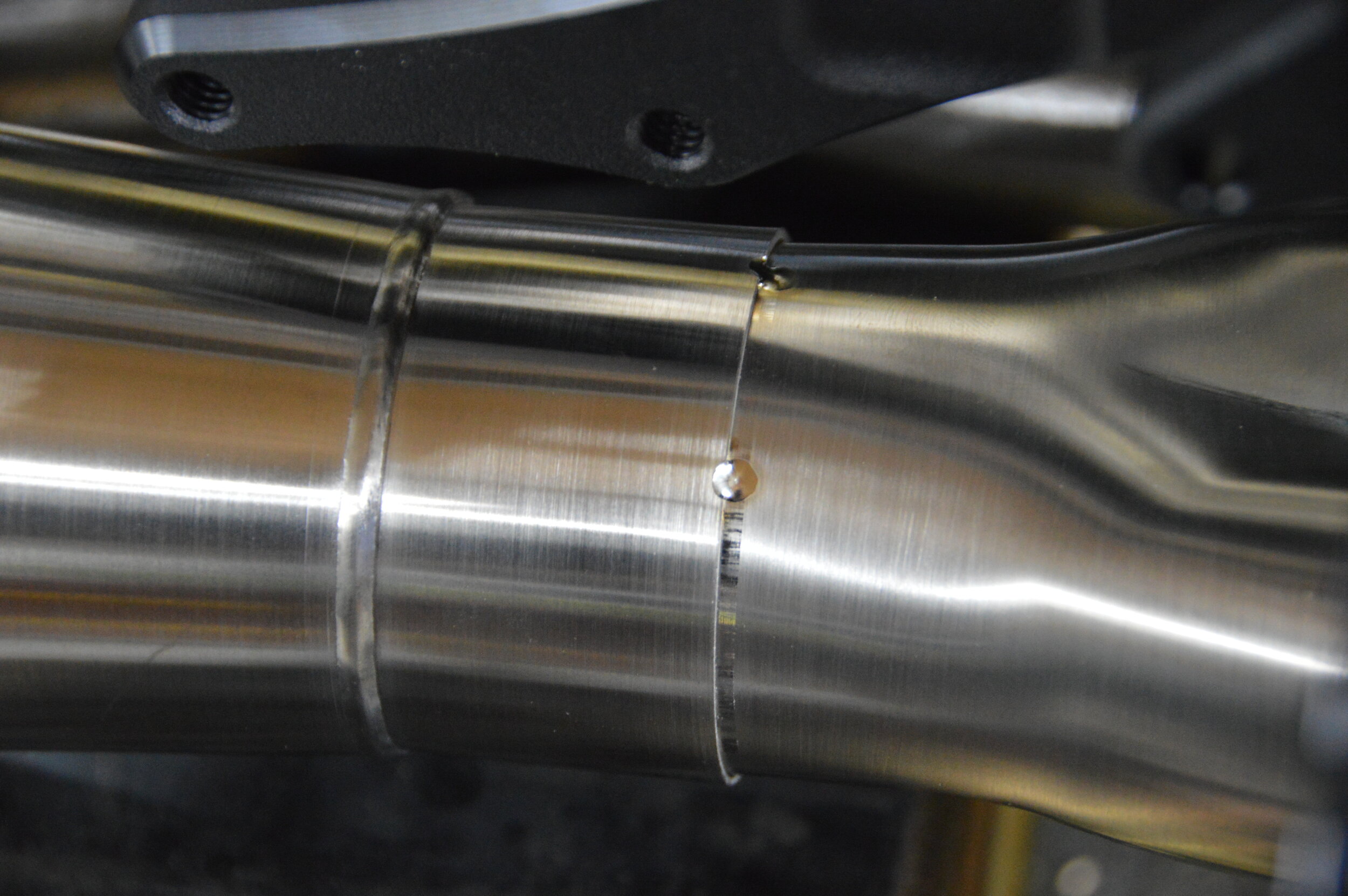

I just happened to be welding up a stainless steel exhaust system from cone engineering for a customer’s SSmall clean tack welds secure the sections in place prior to final weldingportster chopper I was building at this time. After mocking the exhaust up on the bike, I can purge the tubing from the muffler in order to tack and begin welding the system in place on the chopper. Yes, It is necessary to completely purge the exhaust even for tack welding!

Small clean tack welds secure the sections in place prior to final welding

I prefer to weld as much of the exhaust as I can while it is installed on the motorcycle. Stainless steel likes to move a lot as it is welded and keeping it secured to the motor allows me to anticipate warpage and weld in a balanced sequence in order to maintain alignment. I can also do this on the welding table with an entire exhaust fixture system I designed for production.

After completing much of the welding while the exhaust was installed, I’ll remove the system and set up a purge on the welding table.

When purging tubing, it is important that the gas has a place to exit. These aluminum cone plugs made by Street or Strip Concepts have a mesh screen in the center allowing gas to flow out while still maintaining some back pressure in the tube.

Unfortunately, there is really no way for the average customer to determine if a stainless steel exhaust has been properly fabricated or not. Short of cutting the exhaust in half, there is often no way to see the inside of the welds. At the end of the day the only advise is can give is to try and find a shop or individual fabricator who gives you a sense of confidence in their knowledge and pursuit of quality. I know that everyone wants a great deal but please remember that you often get what you pay for. Please feel free to contact us with any questions you may have about stainless steel exhaust fabrication.

Will Ramsey

Faith Forgotten Choppers

812-270-4140